For those who don’t know, a condensing boiler is an equipment popularly utilized by corporations and firms for heating purposes. Condensing boilers are crucial for the proper functioning of such corporations and firms, especially during the winter season when the cold can get in the way of organizations’ productivity standards. Industrial boilers have been a constant presence for numerous types of industries for the past decades and the technology utilized in such has also evolved thanks to the incorporation of modern technology. Modern condensing boilers have been strategically designed to offer a host of additional benefits when compared to some of the more traditional models of industrial boilers. We at hnw.com.au are here to tell our prestigious audience about the various benefits that traditional boilers offer to users when compared to their traditional versions.

If you have recently been anywhere near traditional versioned boilers then you must have noticed how simple the operational functions are in such equipment. Although this might not sound like the end of the world but such limited presence of functions mean a restricted settings option. This leads to a restricted range of settings that can be operated through traditional models of boilers which is not ideal for industries and corporations that require significant flexibility regarding the input of their boilers. Fortunately, this is a particular area where modern condensing boiler completely outperform their updated versions as the former comes pre-installed with a host of different settings options and related functionalities. These additional features mean that modern industries can easily keep up with the flexibility that is demanded from their production processes.

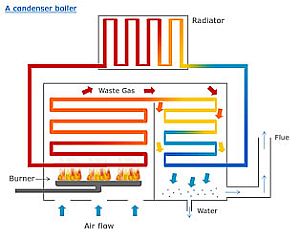

The outdated processes present in traditional models of boilers lack the efficiency levels that are consistently demonstrated through modern condensing boilers. The main reason for such a dilemma is that the process involved in conventional models of boilers lead towards the gradual builds up of moisture which actually transforms into water which gets trapped into tiny spaces found in such outdated equipment. The consequence of such trapped water is that the equipment involved in such a process gets impacted by the forces of corrosion and this leads towards a further loss in efficiency levels for the organization or firm in question. However, modern condensing boilers have actually been designed with such a flaw in mind which ensures that a similar dilemma is not repeated in the modern versions of boilers. Hence, industries can keep up with their production levels while ensuring an efficient structure in place.

Conventional models of boilers were never designed with convenience in mind as such equipment require substantial amount of room and space in order to perfectly fit in an area. This can be very troublesome for a corporation which already has a restricted area to work with in the first place. Fortunately, modern condensing boilers come with a more compact design which assists such restricted organizations in conveniently placing such equipment in their facility.

If your old boiler is consistently giving you and your Organization a tough time then it might be high time for the top management of such corporations to invest in a modern version of condensing boiler. If you wish to seek the perfect replacements for your organization’s outdated and faulty boiler then simply head to hnw.com.au where you can easily check out our full range of condensing boilers.